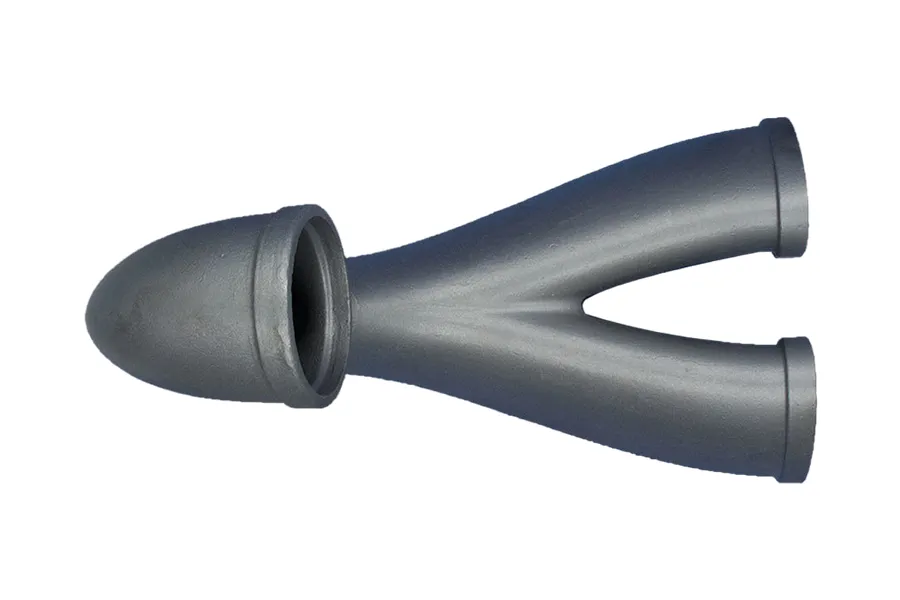

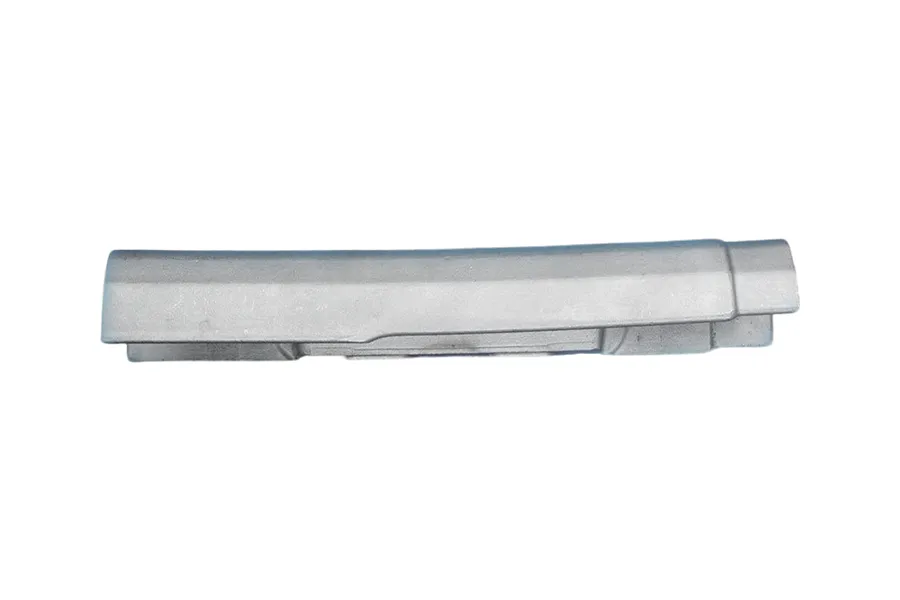

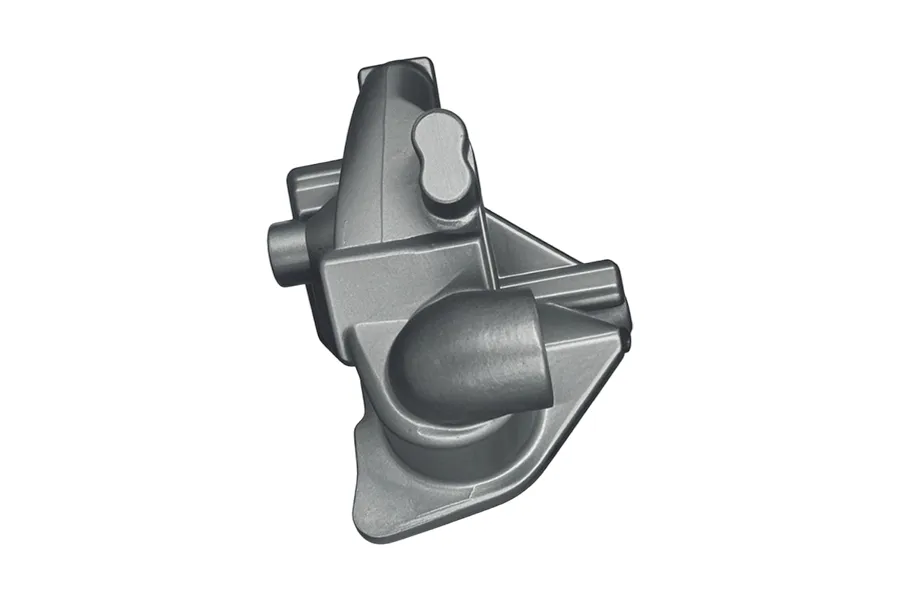

Products

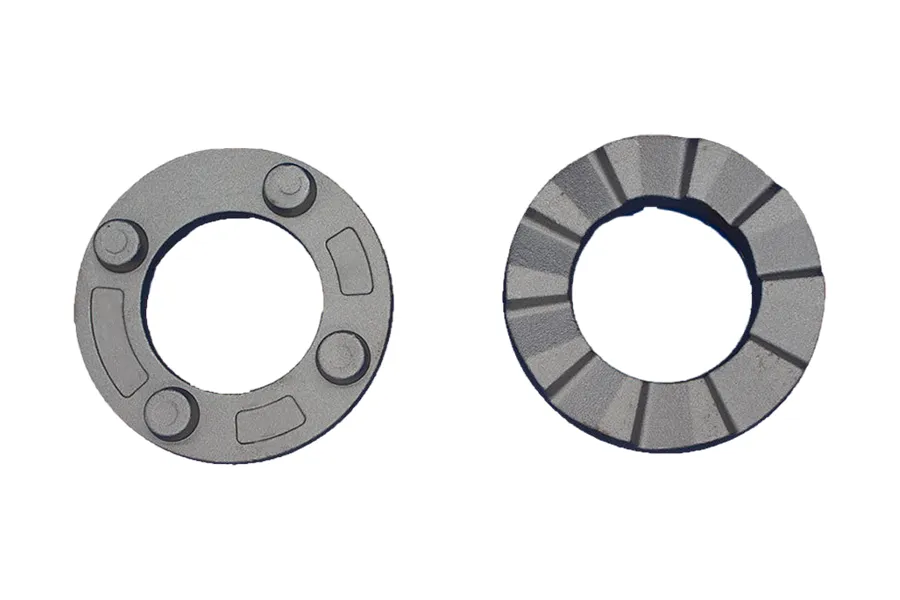

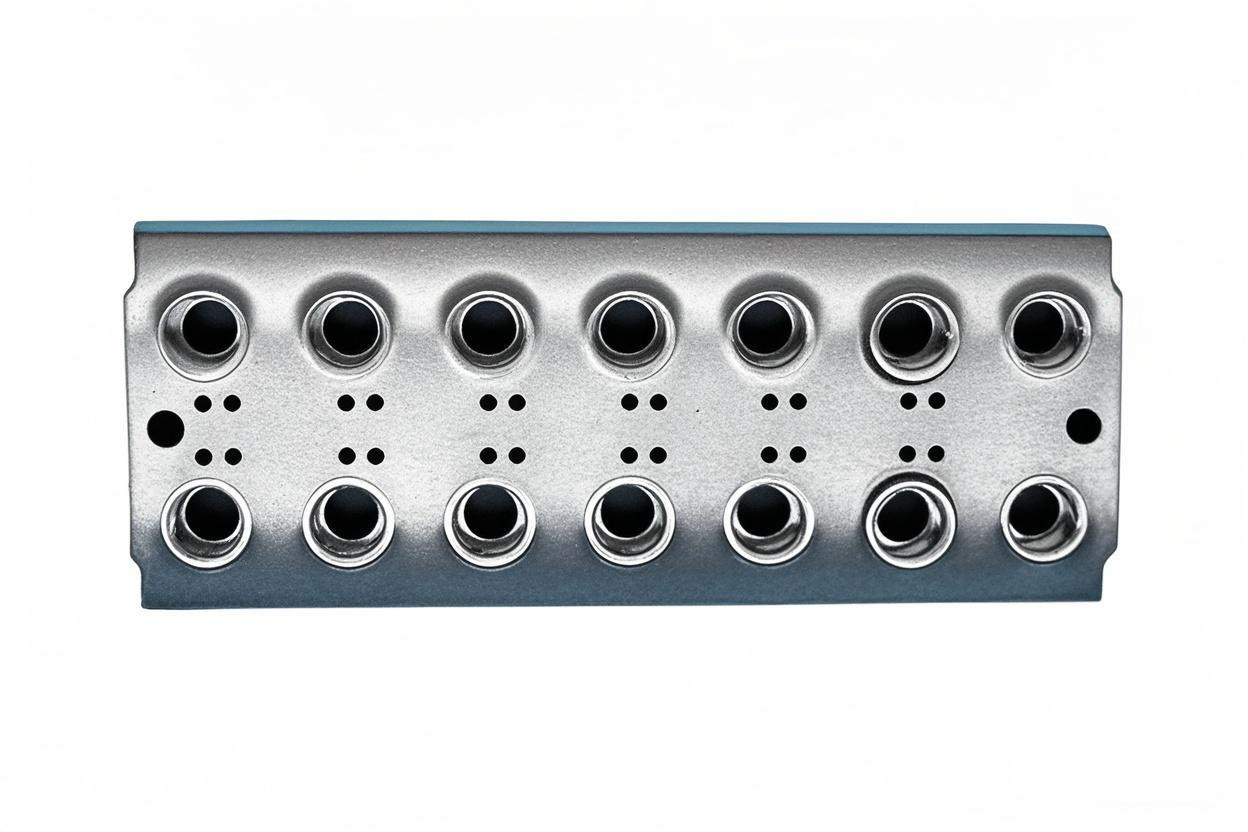

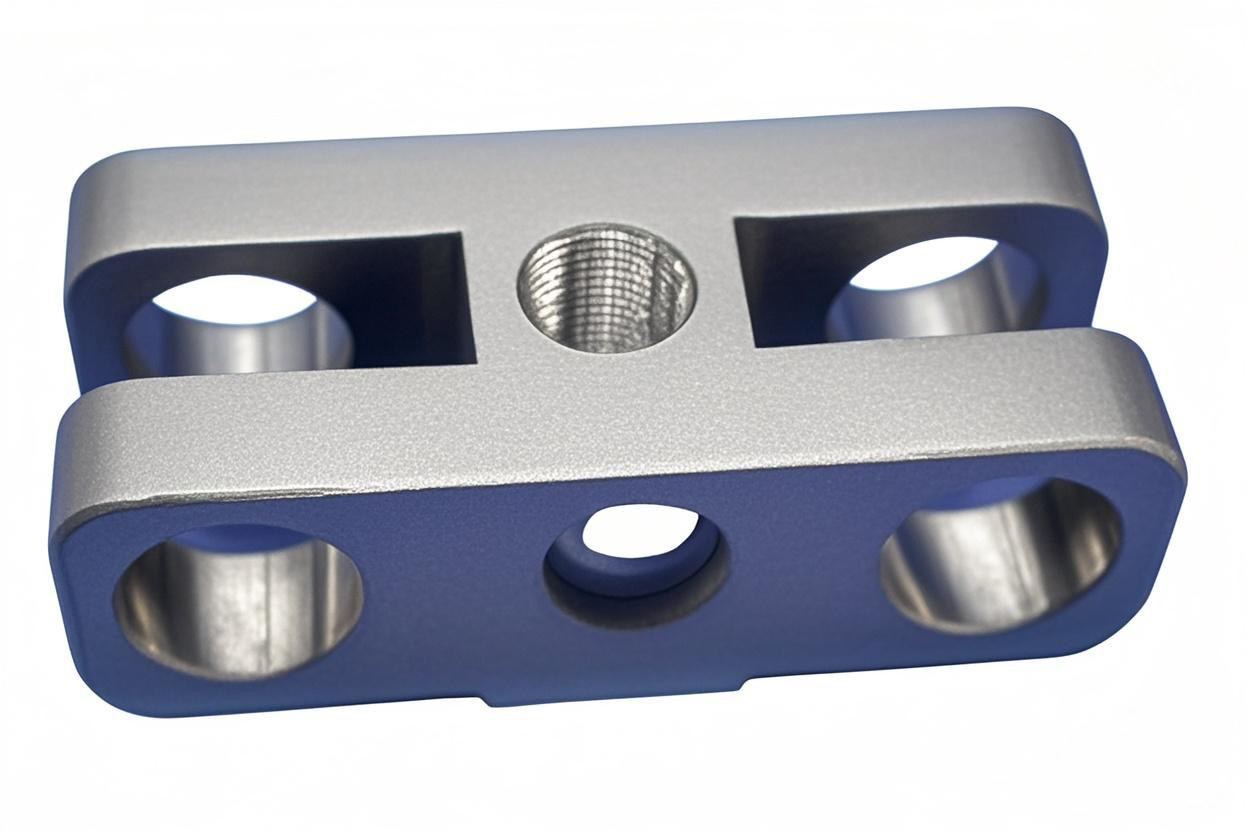

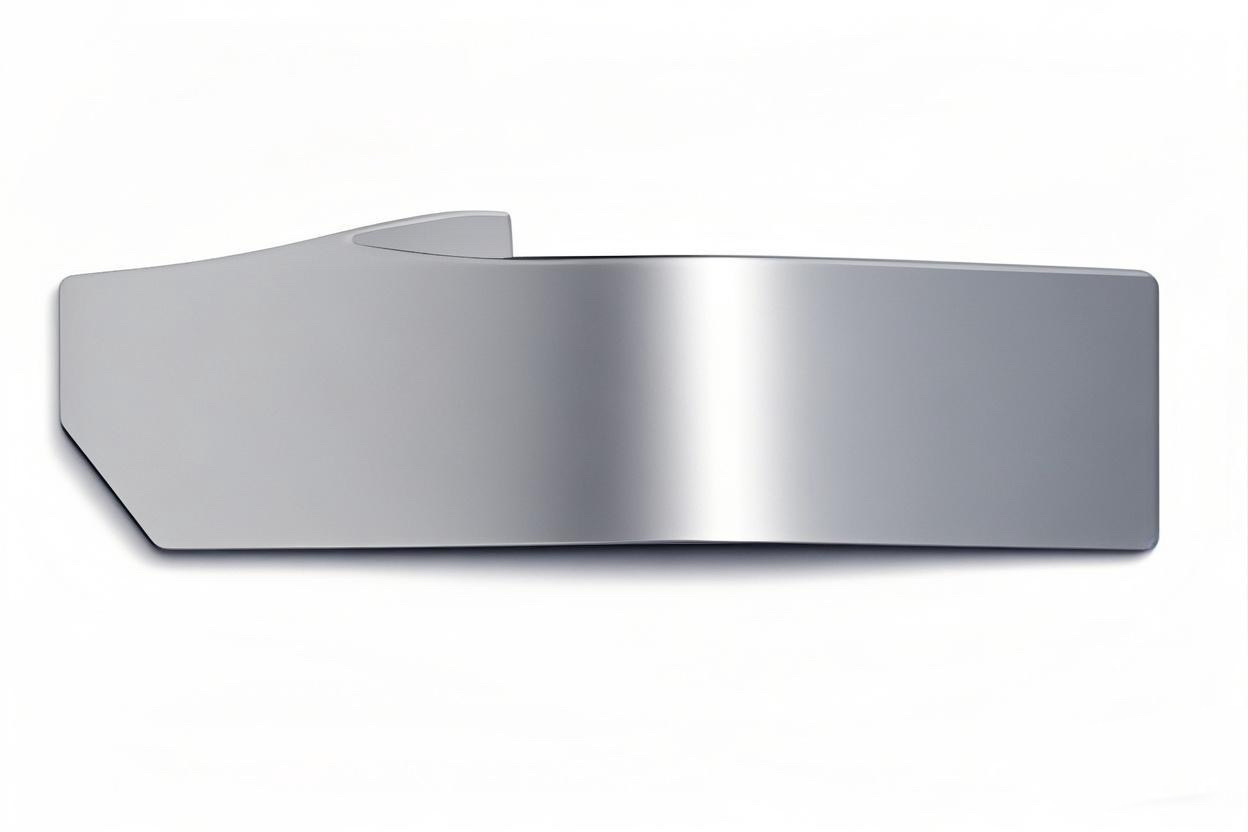

MEDICAL ACCESSORIES

Keywords:

MEDICAL ACCESSORIES

- Details

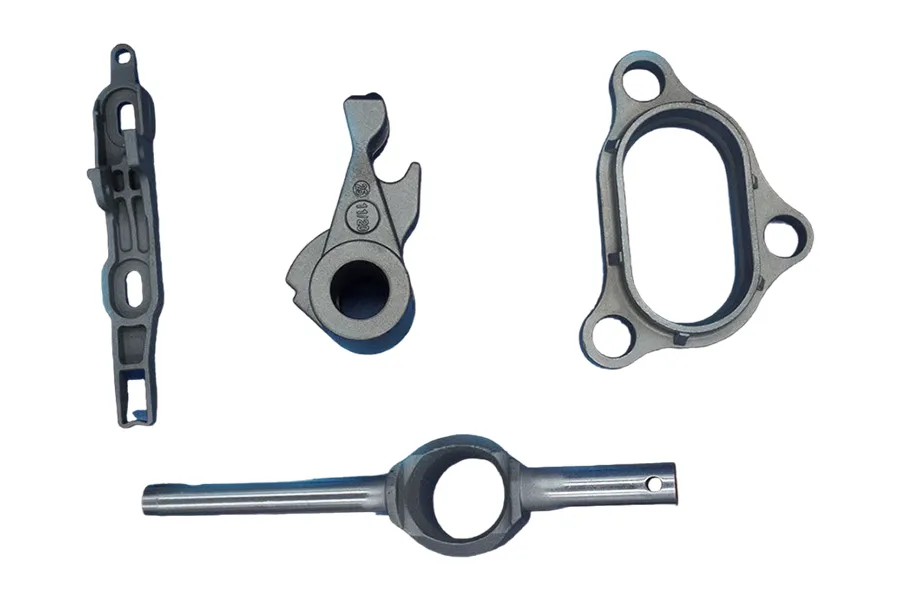

| Casting Process | investment casting (medium temperature lost-wax, silica sol) |

| Material | carbon steel, stainless steel, alloy steel, heat-resistant steel |

| Weight | 2g - 150kg |

| Size | Max. 500×500×500mm |

| Wallthickness | min. 2mm |

| Heat Treatment | annealing, diffusion annealing, isothermal annealing, normalizing, solution, Q&T, carbonitriding, nitrocarburizing, nitriding, QPQ, etc. |

| Machining Equipment | lathe, CNC, milling machine, drilling machine, grinder, hacksaw machine, wire-cutting machine, electric discharge machine,machining center, 4-axis vertical machining center, 4-axis horizontal machining center, 4-axis milling center, 9-axis 5-linkgae turning and milling machining center |

| Surface Treatment | shot blasting, sand blasting, glass bead blasting, pickling&passivation, rust protection |

| electropolishing, electrophoresis, vibration grinding, oxidation, brushing, mirror polishing, paint, powder coating, Zinc/Nickel/Chrome plating, PTFE coating, laser marking | |

| Internal Quality Control | chemical composition analysis with Sepctrograph, |

| 100% visual inspection, 100% inspection with go and no-go gauges, checking with caliper, height & depth gauges, feeler gauge, CMM, roughness tester, microscope, etc. | |

| pressure test, salt spray test, MT, PT, RT | |

| hardness test, tensile test, impact test, etc. | |

| Third Party Inspection | according to customers's requirements, such as SGS. |

| Quality Certificates | dimension certificate, 3.1 material certificate, heat-treatment certificate, pressure test certificate, salt spray test certificate, NDE certificates, etc. |

| PPAP Documents | Control Plan, Flow chart, FMEA, MSA, CMK, CPK |

What we do?

Our company is a professional manufacturer of high-quality precision castings made of various stainless steel, carbon steel, low alloy steel. Founded in 2000. our company has over 20 years of professional casting experience.

QA

The company has been certified with ISO9001. ISO14001. PED&AD2000. IATF16949 quality management system.

Quality Control

Our company has about 20 engineering and technical personnel, about 40 quality control and inspection personnel, and is capable of independent development. The company applies the internationally advanced investment casting process-robotic automated silica sol investment casting process. It is a large-scale professional production enterprise of investment casting in China. At present, the annual output of castings is over 1450 tons, and the equipment capacity is 1660 tons.

More Products

Automotive Parts

-

automotive part

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS

-

AUTO PARTS